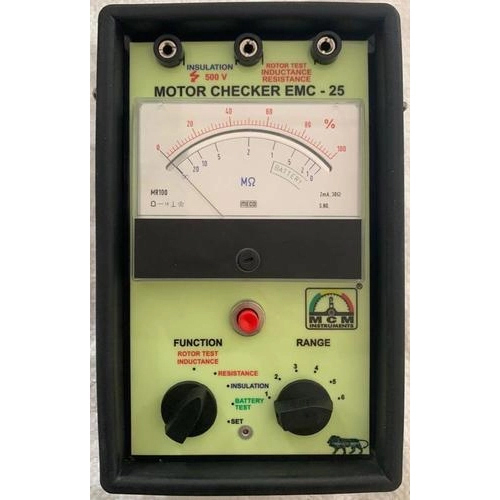

Electric Motor Checker EMC-25

Electric Motor Checker EMC-25 Specification

- Resistant Feature

- Shockproof, Dustproof, Heat Resistant

- Product Type

- Motor Checker EMC-25

- Measuring Voltage Range

- 0 600V AC/DC Volt (v)

- Operating Temperature

- -10C to +55C Celsius (oC)

- Frequency (MHz)

- Up to 50/60 Hz Hertz (HZ)

- Protection System

- Overload Protection, Fuse Protection, Reverse Polarity Protection

- Color

- Black

- Rated Voltage

- Up to 600V Volt (V)

- Dimension (L*W*H)

- 210x125x65 Millimeter (mm)

- Usage & Applications

- Electric Motor Diagnosis & Condition Monitoring

- Weight

- 1000 Grams (g)

- Warranty

- 1 Year

- Frequency

- 50/60 Hz Hertz (HZ)

- Rated Current

- Up to 20A Ampere (amp)

Electric Motor Checker EMC-25 Trade Information

- Main Domestic Market

- All India

About Electric Motor Checker EMC-25

Electric Motor Checker EMC-25

The Electric Motor Checker EMC-25 is a compact, portable device designed to quickly and accurately test electric motors for faults such as winding issues, insulation breakdown, and continuity errors. Suitable for both single-phase and three-phase motors, it features a digital display, durable ABS casing, and overload protection. Ideal for industrial maintenance teams, service centers, and OEMs, the EMC-25 ensures reliable motor diagnostics with minimal downtime.

Fast Checks of On-Site Motors:

- EMC-25 is a portable diagnostic tool for Electrical Engineer and is used for quick on site checks of electric three-phase machines.

- A reduction in machine performance, such as inefficient operation or tripping of overloads, may indicate mechanical or electrical faults. If the fault is electrical the EMC-25 will immediately detect it, without having to dismantle the equipment.

- The EMC-25 may also be used to check quality and condition of motors which have been in storage before they are installed.

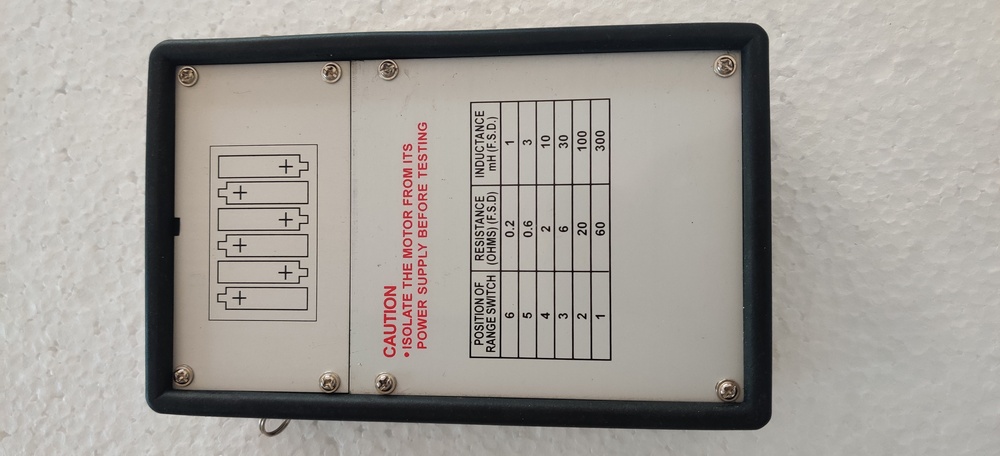

- The instrument has three separate operating modes to measure different types of fault like fully insulation, open circuits / loose

- connections, short circuits and rotor defects. Motor insulation is tested with a high voltage at 500V DC supplied by the instrument

Technical Specifications of Electric Motor Checker EMC-25:

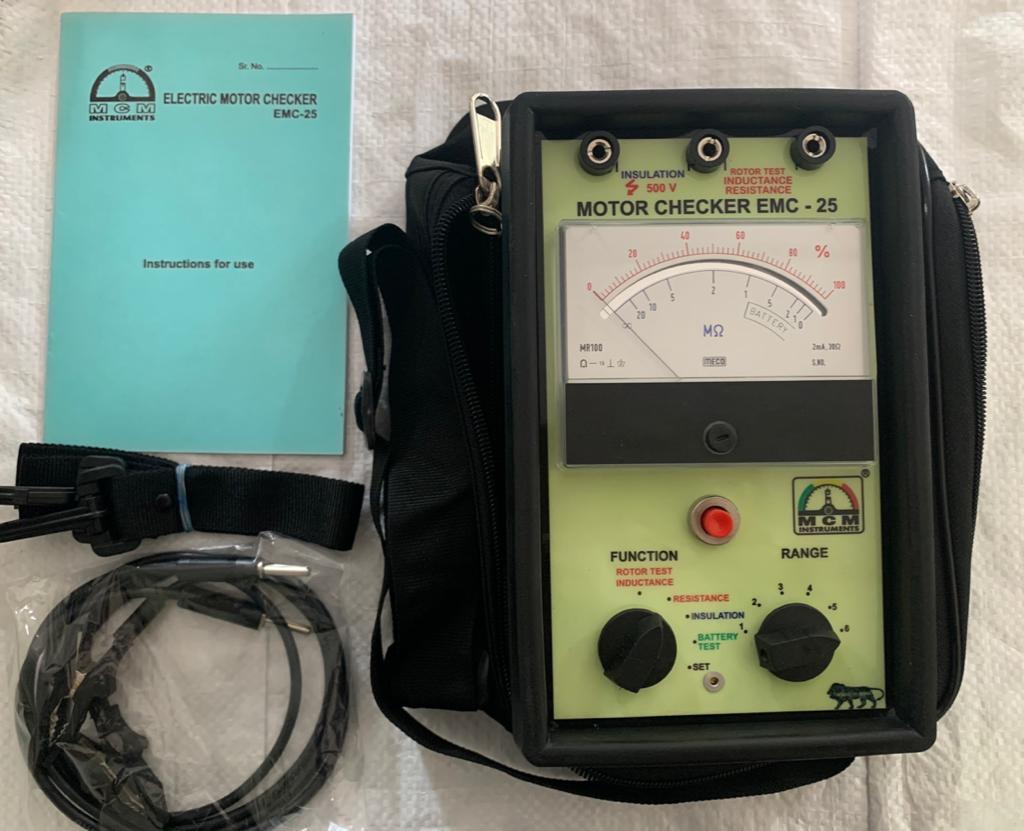

Standard supply:

- Motor Checker EMC-25

- Test Leads (Clips)-1set

- Batteries-6 nos

- Shoulder strap

- Calibration Certificate

- Warranty/ Guarantee Certificate

- Instruction Manual

- Carry Bag.

Comprehensive Motor Diagnosis and Condition Monitoring

The EMC-25 enables precise evaluation of electric motors, offering detailed insights into their operational status and overall health. Designed for easy maintenance and prevention of unexpected failures, it uses advanced detection capabilities to support proactive and routine monitoring in industrial environments.

Superior Protection Features for Enhanced Safety

Equipped with overload, fuse, and reverse polarity protection, the Electric Motor Checker EMC-25 ensures maximum safety during motor diagnosis. Its robust design also provides shockproof, dustproof, and heat-resistant capabilities, minimizing the risk of damage in various settings.

Adaptable for Various Applications and Conditions

Suitable for a wide array of electric motors, the EMC-25 operates efficiently within temperatures from -10C to +55C. Distributors, exporters, and service providers in India trust this device for its compatibility and resilience in demanding industrial and trade conditions.

FAQs of Electric Motor Checker EMC-25:

Q: How does the EMC-25 Electric Motor Checker assist in diagnosing motor issues?

A: The EMC-25 evaluates key performance parameters, allowing users to detect faults, inefficiencies, and irregularities in electric motors promptly. Its detailed monitoring features facilitate early diagnosis, ensuring motors remain in optimal condition and reducing downtime.Q: What protection systems are integrated into the EMC-25 for safe operation?

A: This device includes overload protection, fuse protection, and reverse polarity protection, safeguarding both the user and the motor from common hazards during diagnostic procedures.Q: When should the EMC-25 be used for condition monitoring?

A: It is advisable to use the EMC-25 during scheduled maintenance checks, after repairs, or whenever changes in motor performance are observed. Regular monitoring helps extend motor lifespan and prevents costly breakdowns.Q: Where can the EMC-25 Electric Motor Checker be utilized?

A: The EMC-25 is suitable for industrial facilities, manufacturing plants, and maintenance workshops across India. Its rugged build allows it to withstand challenging environments, making it ideal for use in varied operational conditions.Q: What is the process of checking an electric motor with the EMC-25?

A: To check a motor, connect the EMC-25 to the motor terminals, select the appropriate measuring mode for voltage or current, and observe the diagnostic readings on the display. Follow safety guidelines provided in the user manual for precise and secure testing.Q: What benefits does the EMC-25 offer over standard motor checkers?

A: With its wide voltage and current range, enhanced protection features, and durable construction, the EMC-25 delivers reliable diagnostics and reduces the risk of operational mishaps, providing peace of mind for both technicians and business owners.Q: Who distributes and supports the EMC-25 in India?

A: Manufacturers, distributors, exporters, wholesalers, and service providers across India offer the EMC-25, ensuring local availability, after-sales support, and warranty services for end users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Motor Checkers Category

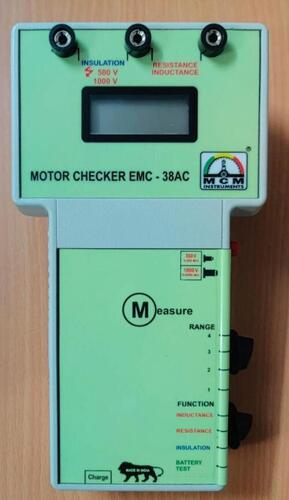

Digital Motor Checker EMC-38AC

Price 28300.0 INR / Number

Minimum Order Quantity : 5

Weight : 750 Grams (g)

Product Type : Bearing Checker BC110TN

Dimension (L*W*H) : 230x100x45

Color : Green

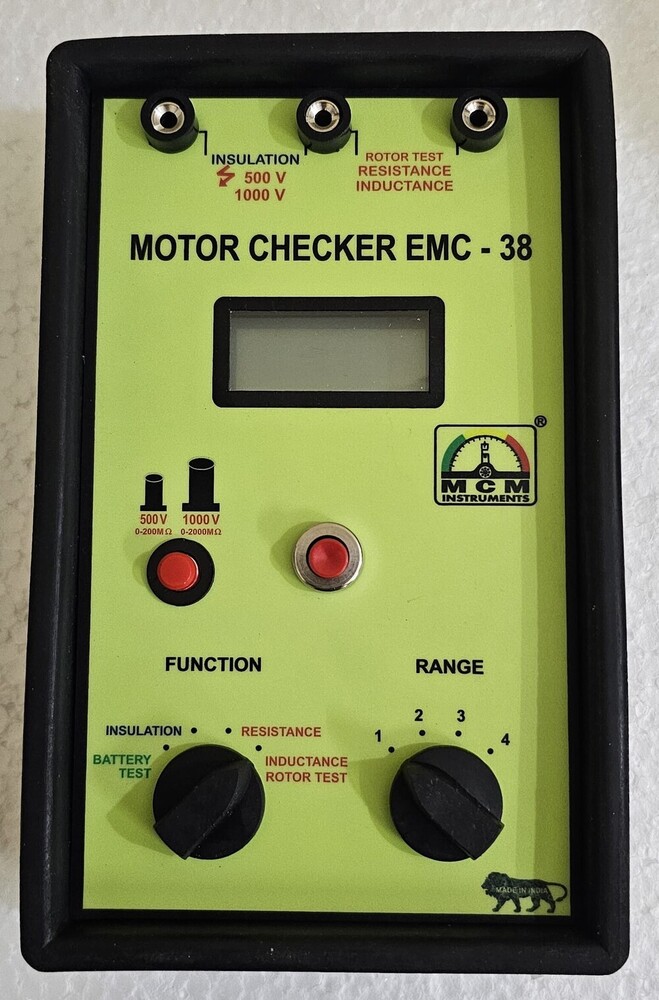

Digital Motor Checker EMC-38

Price 24000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1000 Grams (g)

Product Type : Digital Motor Checker EMC38

Dimension (L*W*H) : 210x125x65 Millimeter (mm)

Color : Black

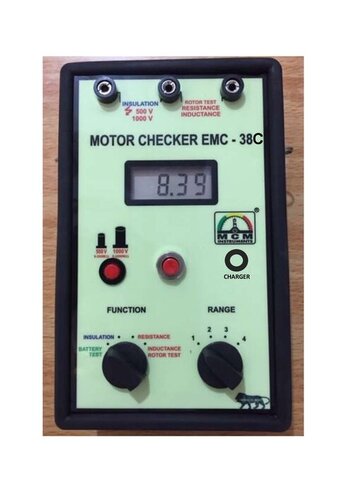

Digital Motor Checker EMC-38C

Price 27000.0 INR / Number

Minimum Order Quantity : 5

Weight : 700 Grams (g)

Product Type : Digital Motor Checker EMC38C

Dimension (L*W*H) : 237x131x45 Millimeter (mm)

Digital Motor Checker EMC-38N

Minimum Order Quantity : 10 Pieces

Weight : 700 Grams (g)

Product Type : Digital Motor Checker EMC38N

Dimension (L*W*H) : 237x131x45 Millimeter (mm)

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS