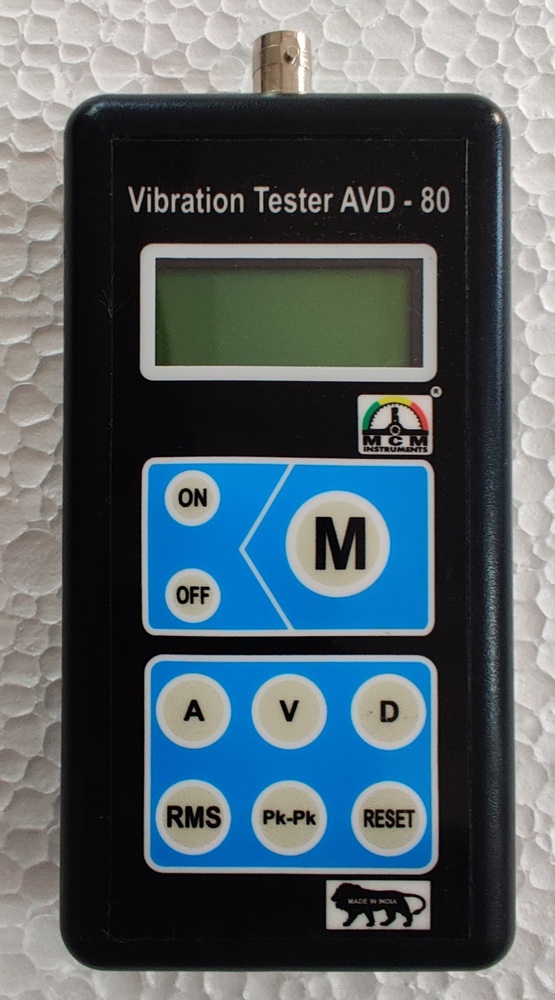

Vibration Tester AVD-80

Vibration Tester AVD-80 Specification

- Application

- Package and material vibration resistance test

- Operate Method

- Automatic

- Gas Pressure

- 0.5 MPa

- Number of Specimens

- 1~3

- Resolution

- 0.01 mm

- Product Type

- Vibration Tester

- Measuring Range

- 0.1 ~ 20 mm

- Usage

- Industrial

- Automation Grade

- Automatic

- Response Time

- Instantaneous

- Humidity

- 20% ~ 90% RH (non-condensing)

- Frequency

- 2~5 Hz

- Test Range

- 0.1 ~ 5 mm

- Operating Voltage

- AC 220V 10%, 50Hz

- Specimen Size

- Up to 500 x 500 mm

- Temperature

- 5C ~ 40C

- Power Supply

- Electric

- Hardness

- Standard Hardened steel table

- Features

- Automatic Lock, Overload Protection

- Interface Type

- RS232

- Max Height

- 600 mm

- Color

- Black

- Port Size

- 1/4 inch

- Equipment Type

- Vibration Tester

- Display Type

- Digital LCD Display

- Mounting Type

- Floor Mounted

- Accuracy

- 1%

- Capacity

- <100 kg Max

- Machine Weight

- 80 kg

- Test Speed

- 60-300 cycles/min

- Test Width

- 500 mm

- Test Stroke

- 25 mm

- Control Mode

- Digital control

Vibration Tester AVD-80 Trade Information

- Main Domestic Market

- All India

About Vibration Tester AVD-80

Vibration Tester AVD-80

Vibration TesterAVD -80Micro Controller Based has been designed as simple diagnostic tool for preventive maintenance. The instrument and the monitoring technique are based on the recommendations of ISO standard. Need based maintenance is the latest trend of industry with which maintenance costs are low and life machinery is most optimum. Condition monitoring is basic need for need maintenance.

All three useful measurements are possible. Suitable for monitoring machinery vibration caused by imbalance, misalignment and gear faults. Displacement, Velocity and acceleration modes allow a user to perform basic vibration analysis

Features

- Measuring Vibration: Displacement , Acceleration and Velocity

- True RMS measurement &Peak-Peak

- Sealed Membrane key pad

- Micro Controller based

- Back Light Display

- Auto Off

- Battery Low Indication

- Pocket size and Light weight

Standard Supply :

- 1) Vibration Tester AVD-80 with Pouch,

- 2) Vibration Transducer (Accelerometer) VSF-1F, Magnetic Base, Hand Held Probe Rod, Low Noise Cable with Connectors (1.5 Mtrs)

- 3) Manual,

- 4) 9V Battery (Alkaline),

- 5) Test & Calibration Report with Warranty/Guarantee Certificate

- 6) Carry Case.

Superior Safety and Build Quality

The AVD-80 is engineered with an integrated emergency stop and robust protective covers, ensuring user safety during all operations. Its heavy-duty steel testing platform and hardened steel table deliver exceptional durability and stability, making it perfectly suited for rigorous industrial environments. These safety and structural enhancements help minimize workplace risks and extend equipment lifespan.

Advanced Digital Control and Versatile Testing

Featuring a user-friendly digital LCD display and stepless frequency adjustment, the AVD-80 provides versatile and precise control over vibration testing parameters. The machine supports a wide test range and accuracy up to 1%, allowing operators to customize test cycles and strokes for sample analysis. Automation and instantaneous response enhance operational efficiency and repeatability.

Compliance and Wide Application Range

Built to comply with ASTM D999, ISTA 1A, and GB/T 4857.7 standards, the AVD-80 caters to international testing requirements. It accommodates a variety of specimen sizes and weights, making it an ideal choice for applications such as package integrity assessment and material performance evaluation. Its automatic operations and robust controls streamline industrial testing processes.

FAQs of Vibration Tester AVD-80:

Q: How does the safety system of the AVD-80 enhance operator protection during testing?

A: The AVD-80 is equipped with an emergency stop button and robust protective covers, which immediately halt operation in emergencies and shield users from moving parts. This significantly reduces the risk of accidents and injury, ensuring safe, worry-free testing in industrial settings.Q: What standards does the Vibration Tester AVD-80 comply with, and why is this important?

A: The tester complies with ASTM D999, ISTA 1A, and GB/T 4857.7 standards, ensuring that vibration resistance testing meets international benchmarks. This compliance is vital for companies needing standardized results for global trade, quality assurance, and regulatory requirements.Q: When is it ideal to use the AVD-80 for vibration resistance tests?

A: The AVD-80 is best utilized during material development stages, pre-shipment inspections, or when validating packaging integrity under simulated transportation vibration conditions. Its wide operating temperature and humidity range allow use in varying industrial environments year-round.Q: Where can the results from the AVD-80 be applied in industry?

A: Results from the AVD-80 are essential in packaging R&D labs, quality control departments, and by exporters to ensure products withstand transit-induced vibrations, preventing damage and ensuring customer satisfaction. Theyre especially crucial for manufacturers and suppliers in logistics-heavy sectors.Q: What is the process for conducting a vibration test with this equipment?

A: Place the specimen (up to 500 x 500 mm and 100 kg) on the platform, set the required vibration parameters using the digital control, and start the automatic sequence. The machine simulates vertical vibrations at the desired frequency and stroke, recording performance data for assessment.Q: How does the stepless frequency adjustment benefit the testing process?

A: Stepless frequency adjustment offers precise control over vibration speed (60300 cycles/min), allowing tests to mimic actual transport or handling conditions closely. This flexibility leads to more relevant, customizable test results and better product quality assurance.Q: What are some key advantages of using the AVD-80 in industrial applications?

A: Key benefits include robust safety features, high test accuracy (1%), real-time digital display, instant response time, and compliance with leading standards. Its automatic operation and heavy-duty construction ensure reliable, efficient testing with minimal manual intervention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibration Tester Category

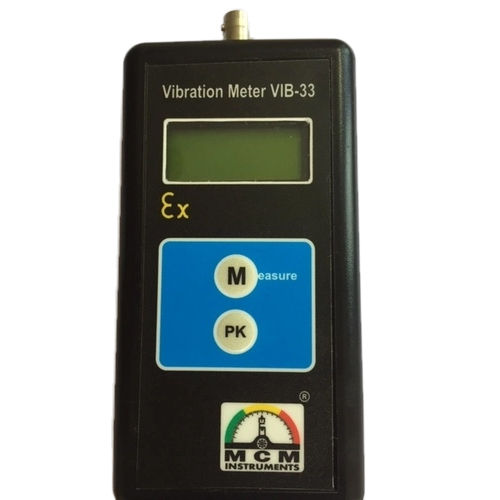

Vibration Meter VIB-33 EX

Product Type : Vibrometer VIB33 EX

Color : Black

Usage : Industrial

Power Supply : Electric

Vibration Meter VIB-30 Plus

Product Type : Vibration Meter VIB30 PLUS

Color : Black

Usage : Industrial

Power Supply : Electric

Weight : 200 Grams (g)

Dimension (L*W*H) : 135x70x25 Millimeter (mm)

Digital Vibrometer VIB-40

Product Type : Digital Vibrometer VIB40

Color : Red

Usage : Industrial

Power Supply : 9V 6 F22

Weight : 200 Grams (g)

Dimension (L*W*H) : 135x70x25 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free