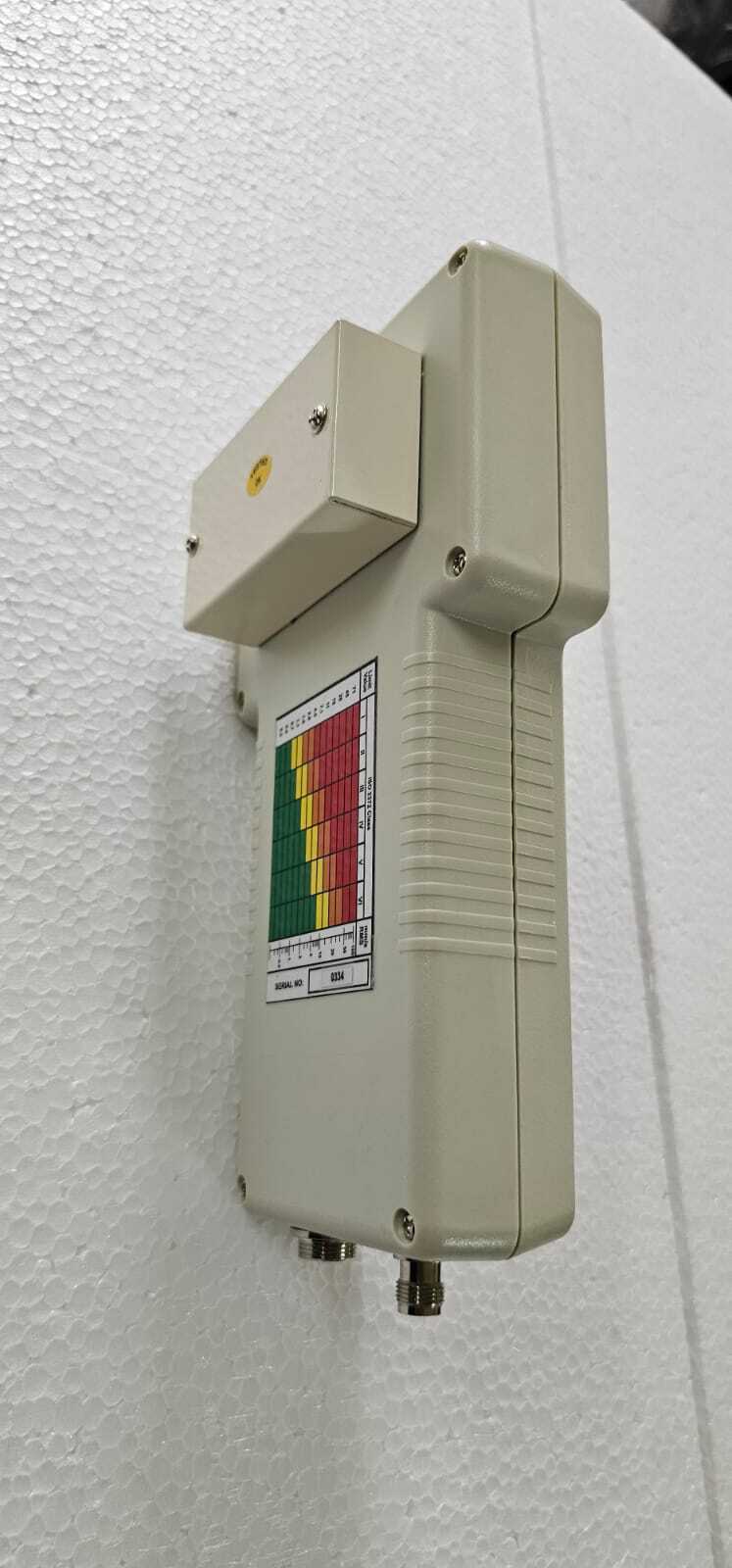

Bearing Checker BC-110TN

Price 97500.0 INR/ Number

Bearing Checker BC-110TN Specification

- Product Type

- Bearing Checker BC-110TN

- Power Supply

- Lithium Ion Rechargeable Battery

- Weight

- 750 Grams (g)

- Dimension (L*W*H)

- 230x100x45

- Usage

- Industrial

- Operate Method

- Automatic

About Bearing Checker BC-110TN

Bearing Checker BC-110TN

Shock Pulse, Tachometer, Infrared Temperature & Electronic Stethoscope

Features:

Shock Pulse Measurement

(Mechanical & lubrication, damage development of bearing)

Laser Tachometer measurement

Infrared Temperature measurement

Direct indication of machine condition

in terms of good reduced-bad in bearing function

Stethoscope (Mechanical sounds detection) For easy location of machinery noise in Industrial environment

Microprocessor based

Back light LC Display

Auto Off

Battery Low Indication

Bearing Monitoring:

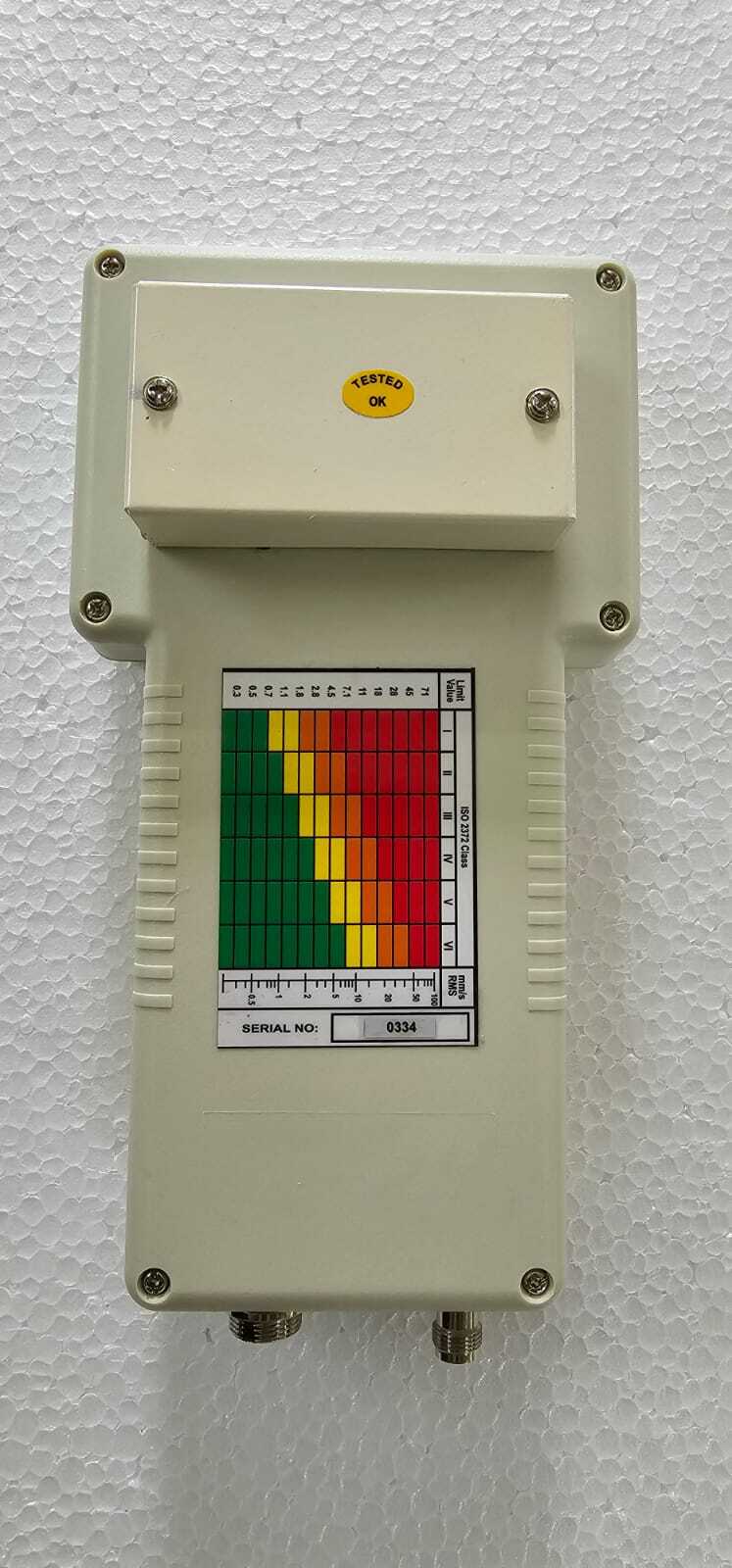

Bearing Checker BC-110TN gives a direct indication of bearing condition on a green-yellow-red scale which allows an instant distinction between good and bad bearings. Thus, the BC-110TN is equally suitable for fast routine checks and for the detailed analysis of critical bearings, supplies digital shock value readings plus accurate information on lubrication condition and damage severity readings for rolling bearings.

Early bearing damage detection: The main purpose of bearing condition measurements is the detection of individual damaged bearings in time for a planned replacement. This method is less expensive and more reliable than periodic replacements, because a bearing that has not failed before its scheduled replacement is likely to be serviceable for a long time

The Bearing Checker BC-110TN indicate bearing damage by displaying:

an arrow against the red sector of the condition scale

(SI) a severity index number which increases with the severity of surface damage.

(BS) Bearing Status D = typical damage pattern detected

Analyzing lubrication condition: The fact that the service lift of bearings is mainly dependant on lubrication is well known. Very large sums can be saved if bearing life can be extended by improving lubrication. The Bearing checker 110TN displays a lubrication number(LFT) which increases in proportion with the thickness of the lubricant film between the rolling elements and the raceway in the loaded part of the bearing

Infrared Thermometer probe: The Infrared Temperature Probe is a noncontact temperature measurement

Laser Tachometer : The Laser Tachometer probe is a noncontact tachometer measurement

Electronic Stethoscope: The need to eavesdrop on mechanical sounds within machinery is essential in any maintenance department. Mechanical faults can often be heard. The problem is to locate the sound source quickly and accurately in a generally noisy environment. The electronic stethoscope is a sensitive listening stick, for location of all kinds of machinery noise. Valve chatter, tappet noise, piston slap, gear and pump noise and the operation of relays and solenoids are just a few of the many noises that may be traced, amplified and assessed with this device.

Technical Specifications

Shock Pulse Function: Measuring Range: -19 to 99 dBpv

Electronic Stethoscope: (Noise) Frequency Range

Resolution: 1 dBpv

30 HZ to 20KHZ

Head set: Stereo type

Infrared Temperature: Measuring Range: 0 - 550C

Display: 4 x 16 line back light dot matrix LCD

Resolution: 1C

Operating Temp. Range: 0 - 55C

Accuracy: +/- 2% of reading or 2 C

Sealed Membrane key pad

Field of View: D/S = Approx. 8:1 ratio

Input Connectors: TNC & Round

Size: 230x100x45 mm

Laser Tachometer: Measuring Range: up to 20,000 rpm

Weight: 750gms (Approximately)

Resolution: 1 rpm

Power Supply: Lithium Ion Rechargeable Battery

Accuracy: +/- (1 rev. + 0.1% of reading)

Casing: ABS

Standard Supply

Bearing Checker BC-110TN

With protective cover

Shock Pulse Probe - 1no

Head Phone - 1no

Laser Tachometer Probe - 1no

Infrared Temperature Probe - 1no

Noise probe road 1no

Charger - 1 no

Instrument Manual - 1no

Test & Calibration Report with Warranty

Guarantee Certificate

Carry Bag

Effortless Automatic Operation

BC-110TN simplifies bearing inspection with its fully automatic operating method, reducing the time and expertise needed for accurate analysis. The device detects faults quickly, helping maintenance teams act promptly. Its lightweight design makes it easy to carry, further supporting efficient operations in industrial environments.

Designed for Industrial Versatility

With robust construction, the BC-110TN fulfills the needs of a wide spectrum of industries. Its compact size allows for easy handling and usage even in tight spaces, addressing the challenges of industrial sites. This device ensures reliable condition monitoring for extended machinery life.

Reliable and Rechargeable Power

The integrated lithium ion battery provides lasting power, ensuring the device remains operational during lengthy inspection routines. Quick recharging minimizes downtime, making the BC-110TN highly practical for routine preventative maintenance schedules.

FAQs of Bearing Checker BC-110TN:

Q: How does the Bearing Checker BC-110TN operate during inspections?

A: The BC-110TN functions automatically, detecting and analyzing the condition of bearings without manual intervention. Its user-friendly interface simplifies operation, making it accessible for both routine and specialized maintenance tasks.Q: What benefits does the BC-110TN offer in industrial applications?

A: This device enables early detection of bearing faults, helping industries avoid unexpected machinery breakdowns. By ensuring optimal bearing performance, it minimizes maintenance costs, extends equipment lifespan, and boosts overall productivity.Q: When should the BC-110TN be used for bearing condition monitoring?

A: The BC-110TN is ideal for scheduled preventive maintenance checks as well as troubleshooting when abnormal machinery vibrations or noises are detected. Regular use keeps machinery running efficiently and reduces downtime.Q: Where can I purchase the Bearing Checker BC-110TN in India?

A: The BC-110TN is available through a network of distributors, exporters, manufacturers, suppliers, traders, and wholesalers across India. You can contact reputable industrial equipment providers or check with official service providers for procurement.Q: What is the process of using the BC-110TN for checking bearings?

A: Simply position the device on the bearing surface and activate it. The automatic operation will analyze and provide a status assessment, allowing for swift decision-making on maintenance or replacement actions.Q: How is the BC-110TN powered and how long does the battery last?

A: It features a lithium ion rechargeable battery, offering extended operational time suitable for multiple inspections on a single charge. Fast charging ensures minimal downtime between uses.Q: Can the BC-110TN be used by service providers for multiple clients?

A: Yes, its compact, lightweight structure and rechargeable power make it an excellent tool for service providers handling maintenance across various client sites.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bearing checker / Shock Pulse Analyzer Category

Shock Pulse Analyzer BVT-111

Power Supply : Electric

Product Type : Shock Pulse Analyzer BVT111

Color : Red

Usage : Industrial

Operate Method : Automatic

Hardness : Up to 62 HRC

Bearing Condition Analyzer BVT-111N

Power Supply : Electric

Product Type : Bearing Condition Analyzer BVT111N

Color : Red

Usage : Industrial`

Operate Method : Automatic

Hardness : Applicable for all standard bearing grades

Shock Pulse Analyzer-888

Power Supply : 9V 6 F22

Product Type : Shock Pulse Analyzer888

Color : Yellow

Usage : Industrial

Operate Method : Automatic

Hardness : Yes

Bearing Condition Analyzer-110

Power Supply : Electric

Product Type : Bearing Condition Analyzer110

Color : Red

Usage : Industrial

Operate Method : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS